Walbro designed the WB-3A carburetor specifically for use on 2-cycle racing karts. It has become virtually standard on karts using the Yamaha KT100 or HPV engine.

Please Note: We no longer supply parts or rebuild kits for these carburetors. This article is for referene only.

Tools Needed

Flat blade screw driver

Phillips head screw driver

Magnifying glass or Spark Plug Magnifying Light, Part No. 1308

Small pick or safety pin

Walbro Fulcrum Height Gauge

Carb cleaner

Compressed air source

Rubber or nitrile gloves that are resistant to carb cleaner

Safety glasses

Before You Begin

Find a smooth flat surface free from children, pets, strong wind or anything that can cause very small parts to disappear quickly. Cover this workspace with a white towel, or paper towel, and disassemble and reassemble the carburetor in this space only.

Depending on the extent of your planned rebuild, select either a complete rebuild kit or a simple gasket kit. This article will demonstrate a complete rebuild of a Walbro WB-3A.

|

TipWhen removing the carburetor, label the pulse and fuel hoses so that you get them reconnected properly after the rebuild is complete. |

|

Step 1Begin by removing the four (4) Phillips head screws that secure the large rectangular cover with the silver pulse line fitting in it. Remove the cover and its two gaskets and place aside. Yes, there are two gaskets! This can be hard to see if it's your first time doing this. As a matter of fact, all three covers that you'll remove utilize one gasket and either a rubber or PTFE membrane mated to it. |

|

Step 2Use a small dental pick to carefully pull the filter screen out of the 1/4 inch diameter fuel runner by prying under the small lip on the outer edge. Snagging this edge with the pick will reduce damage to the filter and allow you to reuse it. TipBlow any contaminants or debris free from the screen with just your mouth, do not use compressed air as this tiny of a part will likely be blown out of your hand. |

|

Step 3ATurn the carb over to expose the smaller round cover and position the carb with the high and low speed adjustable needles pointing to your left. Remove the four Phillips head screws. Before lifting the cover off, see Step 3B. |

|

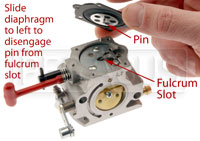

Step 3BIf the gasket and diaphragm go with the cover, gently lift up and to the left to disengage the diaphragm from the fulcrum arm. You'll notice that the diaphragm pin has a notch cut in it that seats in the slot at the edge of the fulcrum arm. If you pull straight up, you could bend the fulcrum arm. Remember this also when reassembling. |

|

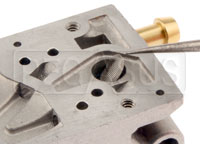

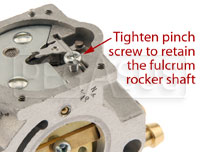

Step 4ANow loosen the small Phillips head pinch screw that secures the fulcrum arm rocker shaft. (There is no need to fully remove it). |

|

Step 4BTake a pick or very small screw driver and pry the shaft up and out of its slot in the carb body. When removing the fulcrum arm and shaft, note that the arm has a fork that fits into the notch in the needle that's positioned directly below it. Carefully ease the fulcrum arm from this notch. Remove the needle from its slot. Then carefully remove the spring, using caution not to compress or stretch it. Pop-off pressures rely on the length of this spring, so if you would like to avoid any unwanted adjustments, treat this piece with care. |

|

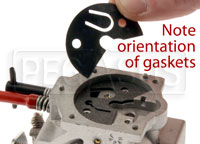

Step 5ANext, remove the two oval head screws that secure the half moon shaped plate. Lift the plate and its gaskets off the body. |

|

Step 5BPay attention to the orientation of the two gaskets under the plate. Keep this orientation in mind during reassembly. |

|

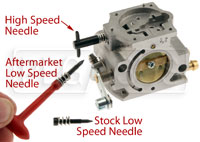

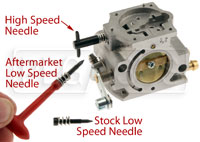

Step 6Direct your attention now to the high and low speed needles on the left side of the carburetor. Two styles of low speed needles are in common use. Your carb may have the small stock low speed needle or the large, red aftermarket needle with T-handle. First remove the low speed needle. There is no washer or O-ring in the port for the low speed needle. Inspect the low speed needle with a magnifying glass and replace if the tip is worn or flattened out. |

|

Step 7Next, remove the high speed needle. Only in the high speed needle port will you find a tiny brass washer and a rubber O-ring. Inspect the high speed needle with a magnifying glass and replace if the tip is worn or flattened out. |

TipExtend the life of your needles by taking precautions not to bottom them out in their ports abruptly. Always use a soft hand when twisting them in, and begin to slow down once you feel you're almost to the end of their travel. Slamming them shut will damage the needles and can also damage the soft aluminum surfaces of the carb body. |

|

|

Step 8Gently coax the brass washer and rubber O-ring from the high speed needle port with a dental pick and set these pieces aside. You have now removed everything that needs to be removed. |

|

Step 9Thoroughly clean the carburetor body. Protect yourself with rubber gloves and safety glasses and make certain that you're in a well ventilated area away from any sparks, open flame or gas appliance pilot lights. Thoroughly clean the entire unit with carb cleaner. Spray the body and all of the ports liberally with the cleaner. All small parts have been removed from the body at this time so rest assured you can completely blow out all orifices with compressed air. Do not dry with a rag or towel. |

|

Step 10Begin reassembly by installing the O-ring and the brass washer into the high speed needle port. |

|

Step 11Now install the high speed and low speed needle valves. Slowly and gently screw the high speed needle in until it bottoms out. Do the same with the low speed needle. From the fully closed (bottomed out) position, adjust each needle to your baseline setting, or 1/8 turn on the high speed needle and 1 full turn on the low speed needle. Note: This is not a recommendation to be used as a final race setting. This is merely a starting point. Your final positioning of these needles will likely vary. |

|

Step 12Place the carb body down on your table again with the needles pointing left and the round body orifice facing up. Drop your new needle into its port. |

|

Step 13Now place your old spring in its port. |

|

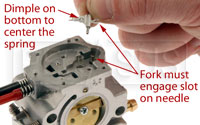

Step 14ADecide whether or not you are going to use your old fulcrum arm and rocker shaft. Replacing them will require some work in getting your pop-off pressures back to where you had them. Using your old set-up should keep you closer to your original setting but a minor adjustment may be needed in any case. Slide the fulcrum arm on to the shaft and pay close attention to the orientation of the arm. The fork on the thin side slides into the slot of your needle, and the fork on the other side must be positioned so the dimple faces down. This depression holds your spring in its proper position. |

|

Step 14BNow tighten the pinch screw to retain the fulcrum rocker shaft. Make sure that as you tighten the pinch screw, the spring remains in position on the fulcrum's dimple. |

|

Step 15Pull out the three half moon shaped gaskets from your kit. One is a rubber membrane and the other two are fiber gaskets. These gaskets are nearly identical except for a slight difference. One has what looks like a stick shift on it, and the other has the same thing but with a 'ball' on both ends. Find the one with 'balls' on both ends and discard it. Historically this gasket has been found to not perform as well as the other. For this rebuild we will only use the gasket with the stick shift on it. |

|

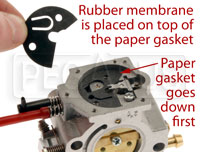

Step 16Place the gasket into its spot first and then put the membrane on top of it. The gasket and membrane will only fit in one direction. Incorrectly placing them in their spot will result in the screw holes for the cover not lining up properly. |

|

Step 17After the gasket and membrane are in place, install the cover plate using two oval head screws. Carefully tighten both screws. |

|

Step 18If you are re-using your old fulcrum, it may not be necessary to check the fulcrum height. However, if you do decide to check the fulcrum height with a Fulcrum Height Gauge, place the round cover gasket down first. Then use the gauge to check the adjustment. If necessary, bend the fulcrum arm to achieve the desired height setting. |

|

Step 19Now find the gasket and diaphragm that matches the round cover and place the gasket down on the body first, then place the diaphragm on top of it. A locating pin in the body determines proper orientation. Make sure the diaphragm pin faces down and engages in the fork at the end of the fulcrum arm. You must gently slide the diaphragm from left to right to engage the groove on the diaphragm pin into the fork on the end of the fulcrum arm. With the diaphragm properly positioned, place the cover on top and evenly tighten the four screws. |

|

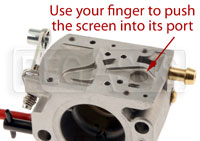

Step 20Turn the carb over while keeping the needles on the left side. Take the new large, round filter screen and gently push it into its orifice with your finger. |

|

Step 21Now find the three rectangular gaskets for the cover. Save the tan PTFE gasket and discard its twin brother made of rubber. |

|

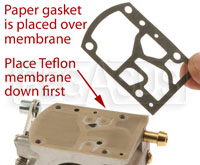

Step 22Place the tan PTFE membrane onto the body first. Place the fiber gasket over it. Make sure the orientation of both are correct. You will notice that they can only be oriented one way due to pins on the cover's edge. Place the cover over the membrane and gasket and fasten with four Phillips head screws. |

|

Congratulations!You have now successfully rebuilt your Walbro WB-3A carburetor. Note: Be sure to connect the fuel and pulse hoses to the correct fittings when reinstalling your carburetor. |

|

Undoubtedly, you will find some pieces that remain from your rebuild kit once the job is completed. This is quite normal and is no cause for concern. Because of this kit's ability to cover several different types of carburetors, there will be pieces that can be discarded. Aside from the gaskets mentioned earlier, feel free to toss out the two solid aluminum discs since they have no use in this application. If you didn't replace your fulcrum arm and shaft then keep the new ones from your rebuild kit for spares. They could come in handy when pop-off pressures need tuning that your old arm can't give you. You may also want to hold on to the small C-clip and screen. These pieces can be found in that half moon shaped cover that you installed in step 17. This screen isn't replaced nearly as much as the larger screen on the other end of the carb, but can cause all sorts of problems if it becomes fouled. |

So how long will my rebuild last?Unfortunately, there is no reliable time line to go by. Ask ten people and you'll most likely get ten different answers. All we can suggest is that you pay close attention to the response of your engine to your ongoing adjustments out on the track. Sometimes simply adjusting your pop-off pressure gives just the response needed. Other times a quick gasket set replacement may breathe new life into it. When adjustments aren't crisp and you're plagued with sluggish performance, or you've just returned from one of the dirtiest tracks around then it may be time for a complete rebuild. Whether you choose to rebuild your carb every weekend or a couple of times each season, it's one of the cheapest ways to be sure that this very crucial element of your kart's engine is performing at its best. |

|